What are the difference between PLC, PCS, and HMIs Interface?

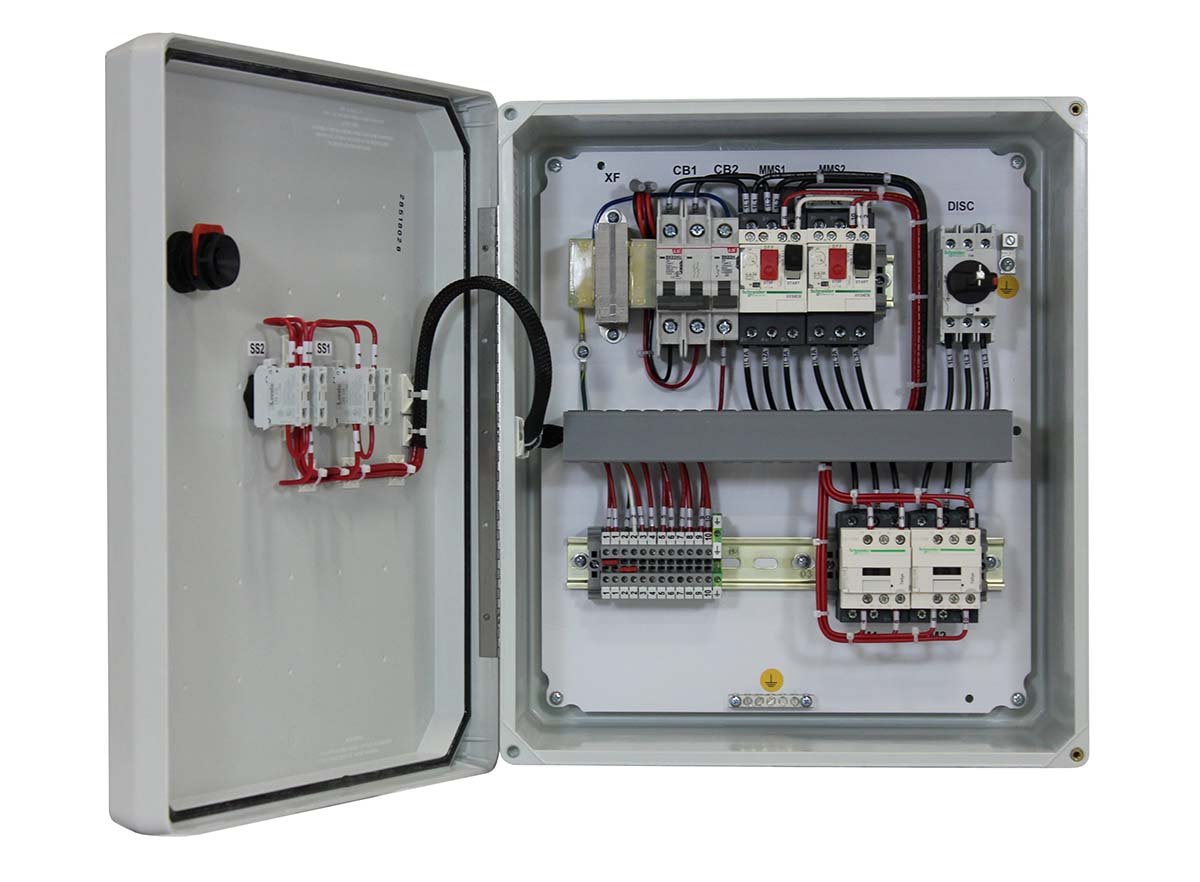

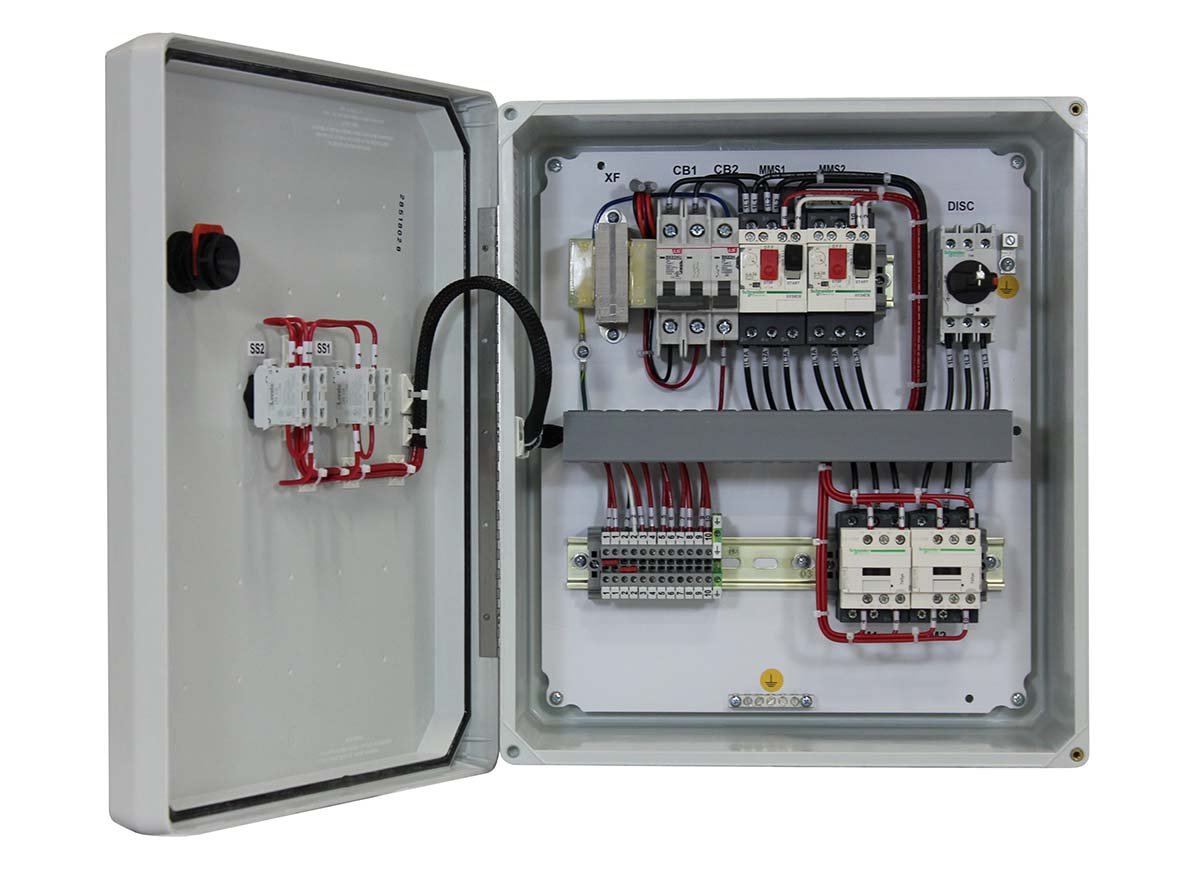

A programmable logical controller (PLC) is a digital computer used for the automation of electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or light fixtures. A PLC is an example of a hard real-time system since output results must be produced in response to input conditions within a limited time and with no missing data.

A process control system (PCS) is an example of "closed-loop" automation. The PCS's code monitors the results from its sensors and sends signals to its actuators as needed, such that any change in its inputs will result in a corresponding change in its outputs.

An HMI is an interface between a human (the operator) and an industrial process, machine tool, or other application. HMIs are employed in most modern production facilities as well as in office environments. The term HMI is often used interchangeably with Human-Computer Interface (HCI) since it is the preferred control method for computer-based equipment such as process control systems and office automation equipment. HMIs are typically based on a personal computer running an industry-specific software package, although increasing integration of PLCs into the system is giving rise to hard real-time HMI functionality.

What are the different types of automation tools available in the industry?

There are several automation tools used in a variety of industries today.

For Manufacturing: PLCs, PCS, robots, programmable automation controllers (PAC), human-machine interface - HMI.

For Process Automation: Cloud-based technology, SCADA system.

For Oil and Gas: Field instruments, DCS systems.

What is automation in the industry?

With increased pressure to cut costs and improve productivity, automation in industry is becoming more widespread. Advances in technology mean that a manufacturing process can now be monitored and controlled remotely – making it easier for manufacturers and oil and gas companies to reduce manual labor and improve safety.

What are process control and automation?

Automation is a method or system in which the operation and control of equipment are made automatically using mechanical, electronic, computer systems. The term has become widespread in industrial applications as well as in commercial operations such as transportation and distribution.

How is automation used in the industry?

Today, we benefit from automation systems in several ways: increased safety, convenience, and productivity. Some of the most common examples include:

o Industrial manufacturing: an automated production line can reduce errors, provide consistent quality products and meet customer demands for speedier delivery.

o Oil and gas: remote monitoring systems allow operators to closely monitor data at oil rigs and production plants around the world. This enables them to avoid dangerous situations such as fire or chemical leaks. Automation also allows increased accuracy in gauging well levels and reduced time in identifying potential harvesting opportunities.

o Robotics: robots can perform an array of manual tasks that would otherwise be extremely dangerous to humans, such as handling hazardous materials or inspecting equipment within a radioactive environment.

o Supply chain management: data-linked backpacks enable employees to collect information on the move, such as measurements and product readings. Combine this with real-time updates of inventory lists and you have a powerful means for improving efficiency and reducing the risk of stock shortages.

What is process control in the industry?

Process control is the use of automation to maintain material properties, such as temperature or pressure. There are various types of process control – including feedback and feedforward – all of which provide different functions:

Positive Feedback: Positive feedback exists when a system's output influences input. For example: if a thermostat detects that the temperature in your room is a few degrees too high, the system will switch on your heater to reduce the temperature. The lower temperature then results in higher output from the thermostat – which turns on your heater even more. In this way, the excess warmth feeds back as input and triggers an increase in output.

Negative Feedback: Negative feedback exists when a system's output counteracts its input. For example, your heating system uses a thermostat to determine the temperature of a room and switches on or off depending on whether it is too hot or too cold. If, however, the heat isn't needed then the thermostat will detect that the temperature is just right – and switch off your heater. In this way, the system's output cancels out its input – preventing it from changing the temperature any further.

Feedforward: Feedforward is a control system in which a feed-forward controller calculates the required future action before receiving feedback from the controlled system. Feedforward controllers aim to predict how a system will respond and preemptively adjust the system to achieve the desired output.

Why is automation good for the industry?

Industrial processes are often dangerous and difficult to monitor, particularly if it requires traveling long distances or entering hazardous environments. Due to this, companies are increasingly turning to automated solutions to improve safety, efficiency, and productivity.

How important automatic control systems are in industrial processes?

There are many benefits to automated control systems in the industry, including the following:

o Increased safety: Remote monitoring allows companies to closely monitor data at oil rigs and production plants. This enables operators to avoid dangerous situations such as fire or chemical leaks, which can lead to serious injuries. Automation also reduces accidents that would otherwise be the result of manually handling hazardous materials or inspecting equipment within a radioactive environment.

o Reduced risk of stock shortages: Data-linked backpacks enable employees to collect information on the move, such as measurements and product readings, which are then automatically uploaded into inventory lists. This improves efficiency by minimizing the time needed for manual updates that can lead to stock shortages.

o Easier process control: By monitoring their various production processes, companies can maintain material properties such as temperature or pressure by using processes such as positive feedback, negative feedback, or feedforward. Process control can help with a range of issues, from ensuring they meet customer specifications to reducing the risk of equipment failure and/or environmental damage.

o Increased productivity: Automated solutions increase the speed and accuracy of actions, which means that companies can produce higher volumes at a faster rate. This, in turn, reduces costs and increases profit margins. The ability to communicate with multiple locations simultaneously via central control terminals also enables companies to respond more quickly to issues as they arise.

o Increased efficiency: Automation can help companies make their workforce more efficient by reducing the number of errors made during everyday tasks, such as reading gauges and labeling containers. In some cases, automated systems within a production line enable workers to focus on high-level duties or management activities – allowing them to oversee multiple processes instead of taking part in individual tasks.

o Higher-quality products: Data logging and trending can also help companies improve product quality by enabling them to spot any defects before they occur and take the necessary action to prevent these issues from recurring. In the case of food production, for example, this could include setting threshold limits on temperature or pressure to prevent spoilage.

o Increased flexibility: Many companies are increasing the number of products they offer, which can lead to greater diversity in production methods and increased complexity in logistics. This makes it difficult for employees to keep track of data while simultaneously ensuring that a production line remains flexible enough to meet changing demands. Automation ensures that all information relating to a particular product is collected together and easily accessible, so employees can adapt workflows as needed.

o Faster disaster recovery: In the event of a disaster, automated monitoring allows companies to quickly identify where equipment has been damaged or production processes have been disrupted – meaning they can focus on shifting resources from unaffected areas to the affected areas to get everything running smoothly again.

o Improved safety standards: Lowering safety risks, reducing environmental impact, and meeting regulatory requirements are all important factors that influence investment decisions in manufacturing automation. Over time, these trends led to stricter legislation on health and safety issues, which has resulted in more manufacturers using automation with built-in safety features to keep people out of harm's way.

o Increased plant efficiency: Automation technologies allow companies to improve their equipment utilization rates by using an automated procedure, which can increase profitability. They also enable them to work for longer periods without compromising production quality or inputting incorrect data into the system – resulting in more consistent finished products.

o Higher quality raw materials: Using automated devices to monitor the production process allows companies to keep a closer eye on their input materials. If they notice that certain ingredients are becoming less effective, for example, they can adjust their blending ratios or switch to different source materials as needed.

What is the role of automation in the industry?

Industrial automation is increasingly popular—and often necessary—for modern industrial facilities. Some of the advantages of increasing industrial automation include:

Analytics collection

Computerized and smart devices can collect more data about your facility and the details of production. This allows facility managers to learn about error rates, production rates, energy usage, and other factors that will help devise efficiency plans.

Improved product quality

Increased safety

More flexibility and capacity

More productivity with Manufacturing Automation

Reduced operational costs

PRODUCTION PROCESS/LINE EFFICIENCY

Each of these advantageous compounds provides greater overall efficiency in the production process. Industrial automation can be included during every step of the line, from initial mixing or production of raw components, to fabrication and machining, to final packaging.

Increasingly smart systems improve line efficiency by taking on specific tasks and alerting human workers when there are signs of a developing problem. This allows employees to spend more time troubleshooting developing problems, creating more efficient processes, and other tasks that require a more creative approach that only a human can offer.

INDUSTRIAL AUTOMATION TOOLS

Every industrial automation system can be custom-crafted to match the facility and the production process at hand. Industrial automation relies upon the different control systems used for integrating the devices or equipment in each process into the larger system. These tools include:

Artificial Neural Network (ANN)