Motor Control Panels

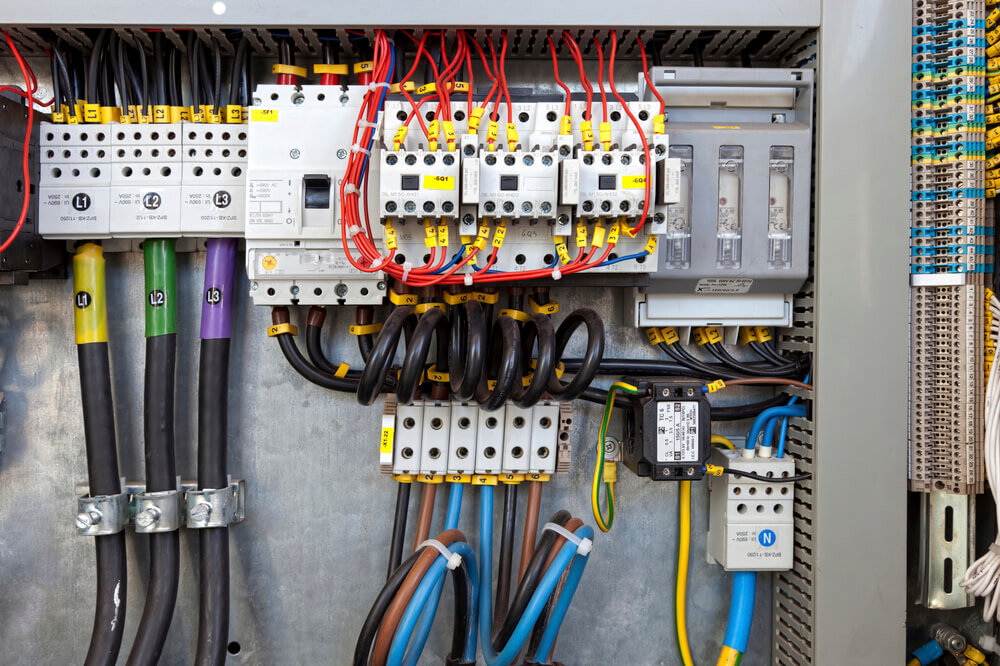

Motor control circuits contain 2 basic parts but not limited to namely a disconnect switch and a motor starter (motor contactor + overload relay). A disconnector can be placed between the power source and the starter. The switch and starter can sometimes be installed on one wall mounted enclosure. Motor starter control panels consist of the following devices:

MOTOR CONTROL PANEL PROJECT

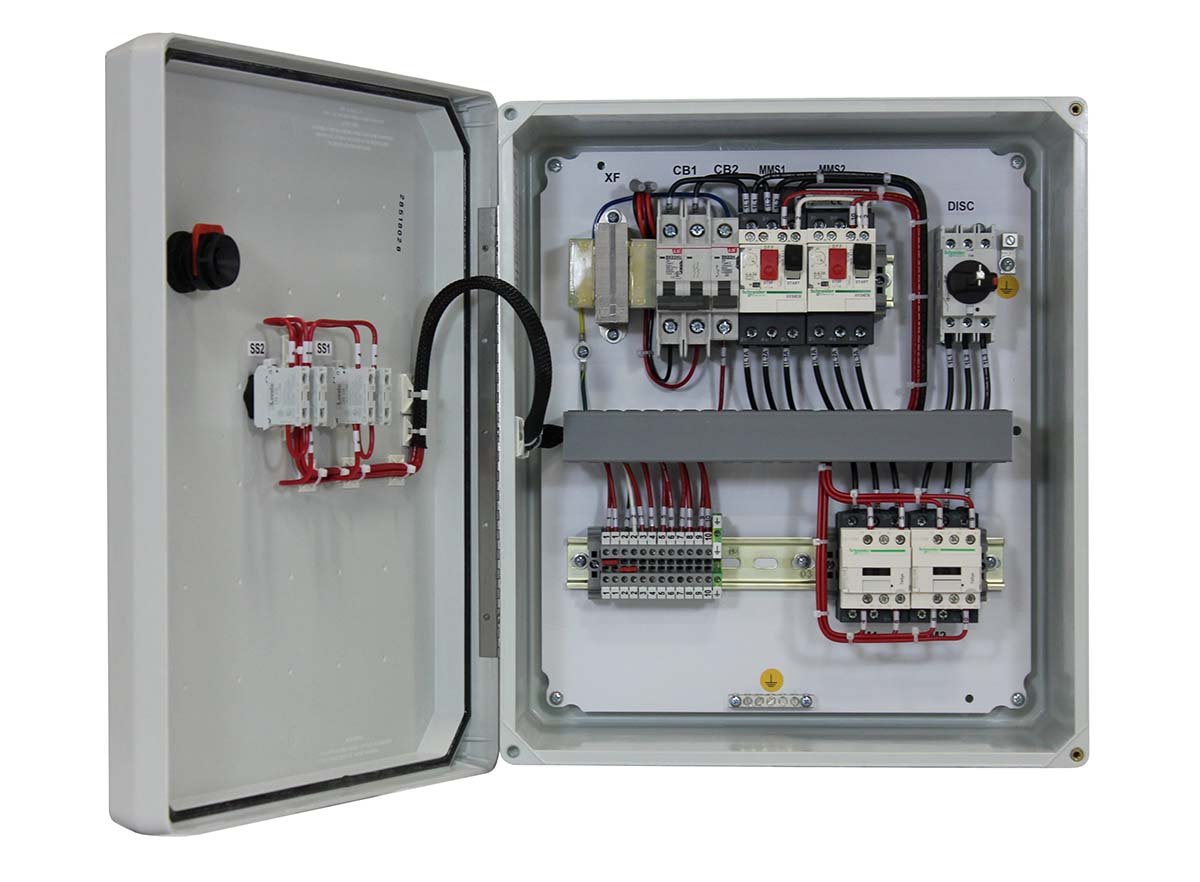

Enclosure

Enclosure for housing all electrical parts.

Equipment enclosures: These are used to protect electrical equipment from weather, vibration, and other sources of damage. Enclosures for hazardous locations: These are specially designed to protect electrical equipment from explosion or fire hazards.

Disconnect Switch

Disconnect Switch typically for shutting down or disconnecting Electricity to the motors.

A disconnect switch is a switch that is used to break an electrical circuit. Disconnect switches are used in a variety of applications, including power distribution, motor control, lighting, and process control. In industrial and commercial applications, disconnect switches are often used to provide a means of isolating equipment from the power supply for maintenance or repair. Disconnect switches are also used as safety devices to prevent accidental energization of equipment.

Contactor

Contactor for starting and stop the electric motors

To start the motor, close the circuit breaker and push the operating handle to the "ON" position. The electric motor will start running. To stop the motor, open the circuit breaker and push the operating handle to the "OFF" position. The electric motor will stop running.

Overload Relays

Overload Relay for shutting down the electric motor in case it overheats

Overload relays are devices that are used to shut down an electric motor in case it overheats. These relays are designed to protect the motor from damage caused by excessive heat. Overload relays are typically used in applications where the electric motor is subjected to high loads or where the ambient temperature is high.

Control Transformer

Control Transformer for stepping down the high voltage into low voltage 480VAC to 120/24VAC.

The control transformer is used to step down the voltage and current in a circuit and provide the necessary regulation to maintain the voltage and current within specified limits. The transformer is designed to operate in either constant voltage or constant current mode. In constant voltage mode, the transformer maintains the voltage at a specified level regardless of the load on the circuit. In constant current mode, the transformer maintains the current at a specified level regardless of the load on the circuit.

Pilot Devices

Mounted on the Door for turning the motor on/off HOA (Hand Off Automatic) control, indicator lights, and other components typical mounted on din rails

Pilot devices are an important part of any motor control system. They provide a way to turn the motor on and off, as well as to disconnect the power to the motor. Additionally, they can be used to isolate the motor from the power supply. Pilot devices are typically mounted on the door of the motor control panel, or on the door of the motor control center. They can also be mounted on the circuit breaker for the motor control system. When selecting pilot devices, it is important to consider the environment in which they will be used. For example, if the pilot device will be used in a wet or corrosive environment, it is important to select a pilot device that is designed for that environment. It is also important to consider the voltage and amperage rating of the pilot device. For example, if the pilot device will be used to control a high-voltage motor, it is important to select a pilot device that is rated for that voltage.

All the devices are wired together into what we call the Motor Control Panel or MCP for short.

What Can We Build For You?

Regardless of your industry or custom control panel needs, IndustLabs has the experience and manufacturing facilities to design and build your custom control panels. We have an experienced engineering and quality control team dedicated to providing the best solution to your custom control needs.

Our manufacturing facility in Dallas, TX are staffed with experienced wiring and installation technicians, ensuring your custom panel meets safety and performance criteria. At IndustLabs, we feature a variety of Motor Control products and panels, if you have questions regarding any of our products, their function or applicability to your project, give us a call, +1 877-945-2272 or contact us for information without obligation.

MOTOR CONTROL PANEL PROJECT