SCADA Systems

Many companies in the early 1990s faced the challenge of managing a network of remote equipment without the cost getting out of control. This challenge led to the development of scada systems. At the basics of scada systems involves a central computer managing remote equipment. The central computer otherwise known as a server typically involves specific software for monitoring, controlling, logging, trending, and alerting of remote equipment.

SCADA Systems Are Used For Which of the Following?

SCADA Systems are used for water management & waste treatment, onshore and offshore gas and oil production, gas pipelines, manufacturing, telecommunications, mining, metals and cement, life sciences and agriculture. In addition to those pillar Industries SCADA systems can be used in any industry you can think of using a single command center for SCADA IoT monitoring and controlling remote equipment. Let's look into more detail of SCADA Systems and how to use it for your equipment.

What is SCADA Systems?

We covered this topic in a previous blog article titled “What is a SCADA? Here is a quick overview...

“SCADA stands for supervisory control and data acquisition, which is a type of computer system that is meant to gather and quickly analyze real-time data. These systems are commonly used within production facilities and industrial plants. When put in use, a SCADA system is designed to help with the control and monitoring of an entire plant or equipment that deals specifically with time-sensitive and critical events. For instance, when a leak occurs in a pipeline, the SCADA system that’s in place will help to detect the leak and transfer the information pertaining to the leak back to a central location.” IndustLabs, https://industlabs.com/news/what-is-scada (follow on twitter)

Where can I get a SCADA system from?

They're many companies that sell SCADA Systems. One particular company that comes to mind is Rockwell Automation FactoryTalk® View SE HMI SCADA software which can communicate on Allen-Bradley ControlLogix® programmable automation controllers (PAC). If your equipment has an Allen-Bradley ControlLogix® programmable controller then this would be a great choice.

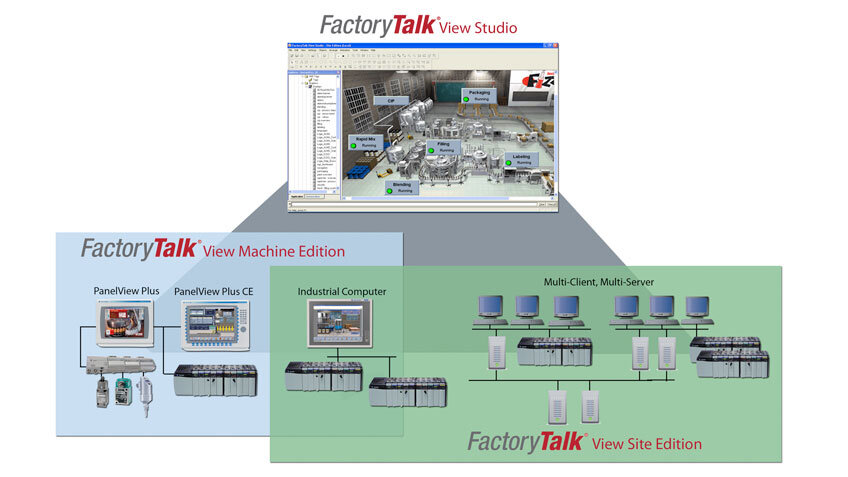

The Rockwell Automation FactoryTalk® View SE HMI SCADA software consists of three major components which are the following:

Connect to your Equipment - FactoryTalk View Studio, you can create network distributed, network station, or local station applications that mirror your plant or process.

Editor your program - Use the editors in FactoryTalk View Studio to create and test the application components you need.

View your virtual HMI- Then set up the FactoryTalk View SE clients to let operators interact with the application after it is deployed.

Here are 3 ways you can get access to the Rockwell Automation FactoryTalk® View SE HMI SCADA software:

Contact Rockwell Automation direct via https://www.rockwellautomation.com/ or by using their technical support number at +1-440-646-3434. Please be advised that you might be required to pay for technical support to Rockwell Automation if you don't have a relationship setup with them.

Contact your local Rockwell Automation distributor via https://locator.rockwellautomation.com/Distributor. You will have to fill a form in order for Rockwell Automation to locate the proper distributor for your area.

Contact IndustLabs via https://industlabs.com/contact-us or by using our support number at (469) 421-4211. Not only can we advise you on your SCADA Systems project but we can sell you all the parts and hardware to go along with your project. In addition, we can also take the project off your hands and do a full-turnkey SCADA system for your setup. Our prices are competitive and our support is next to none.

With the Rockwell Automation FactoryTalk® View SE HMI SCADA software you can develop your human-machine (HMI) application for multiple sites location. This simply means that if your equipment is located at different locations with different network settings then these software packages would centralized all communicate with a central computer or server.

FactoryTalk® View SE HMI SCADA software. Rockwell Automation. 3 May 2020, https://www.rockwellautomation.com/en_NA/news/case-studies/detail.page?pagetitle=HMI-SCADA-Migration-Can-be-Seamless-%257C-Case-Study&content_type=casestudy&docid=5f37d34f3cb7db3fb3cf121fb8c20edd

Overview of Rockwell Automation HMI SCADA Software

Here is an overview of the Rockwell Automation FactoryTalk® View SE HMI SCADA software setup. Depending on what you want to do there are many options. For example, if you already have Allen-Bradley ControlLogix® programmable controllers you can simply use a multi-client and multi-server system architect. You will have to install Rockwell Automation FactoryTalk® View SE HMI SCADA software on a server computer. In the IT world this is known as on premise hosting installation. This means that you have to be responsible for maintaining the computer server at your factory location to include network settings, system updates, security, backups, and software licenses. In addition, you'll have to install FactoryTalk® View SE HMI SCADA software on a Windows computer server. Rockwell Automation recommends several choices. Here are there requirement for the computer server:

Windows 10 Enterprise Intel® Core™ i5 Standard Power processor with minimum of 4 to 8 GB RAM

Windows 10 Professional Intel® Core™ i5 Standard Power processor with minimum of 4 to 8 GB RAM

Most of the time a system integrator will purchase the computer server for the customer since it requires a high level of technical expertise to commission the server with the Rockwell Automation software FactoryTalk® View SE HMI SCADA software package. If you decided that this is the best decision for your equipment and Rockwell Automation software FactoryTalk® View SE HMI SCADA software then here is typical cost breakdown:

Connecting the Equipment and Documentation to your SCADA Systems

Price Range $800 to $1600 for Network Map. The network map shows the installer all the devices that need to be connected to the computer server. It also shows the network configuration of the device to include IP address, Net-mask, and gateway address and such document is essential to a successful project installation.

$7.00 to $10.00 per linear feet of ethernet CAT5 cable installation. Most system integrators will bill you for a minimum of 50 linear feet of ethernet installation per equipment. Therefore be prepared to deal with these costs once you're deciding to run CAT5 ethernet cable from equipment to computer server.

Hardware and Software Cost per site location/ server computer:

List Price of $6,143.00 for Rockwell Automation FactoryTalk® View SE HMI SCADA software for up to 10 HMI client stations

List Price $989.99 for Windows 10 Enterprise Intel® Core™ i5 with 8 Gig of RAM DELL OPTIPLEX 3070 Business Desktop PC

Price Range $200 to $1400 Industrial Router. Most companies will have a router pre-install at their facility so for your project you might not need a router but it is recommended that you get one if you don't have one in place. A network router brings all the ethernet connections into a single device. Therefore it is crucial that you know how many devices you're going to be connecting too and for this you may refer to your network map. For large installations you would typically see a standard router with 26 ports cost around $1,400. For smaller installations you can get by with an 8 port router for a typical cost of under $200.

Integration and Programming Cost for your SCADA Systems

Price ranges $1200 to $1800 to install Rockwell Automation FactoryTalk® View SE HMI SCADA software on the computer server

Prices range $150.00 to $225.00 per hour for programming the application. If you have a large facility and require multiple programmers then please be aware that the programming cost will increase based on the amount of programmers needed for the project.

Are you ready to grow your operations with HMI SCADA Systems?

You now know what a SCADA System is and the benefits of your operations. You know what to look for when choosing SCADA Systems and the cost associated with it. And you've also seen Rockwell Automation HMI SCADA software which is of the best SCADA Systems out there for water management & waste treatment, onshore and offshore gas and oil production, gas pipelines, manufacturing, telecommunications, mining, metals and cement, life sciences and agriculture industry. Let's take the next step.

Think all SCADA Systems are all the same? Think again. Eliminate costly mistakes by having IndustLabs expertise on your side to transform your operations to the modern age.