What is Industrial Automation?

Industrial Automation

Industrial automation is the use of robotics, machines and control systems to perform tasks that were traditionally carried out by human workers. Automation can improve productivity, quality and safety in manufacturing and other industrial applications.

Automation technology includes a wide range of tools and technologies, such as robots, numerical control (NC) machine tools, programmable logic controllers (PLCs), computer numerical control (CNC) systems and industrial sensors. Automation systems can be integrated into existing production lines or stand-alone and can be used to collect data for preventative maintenance of the equipment.

Industrial automation offers a number of benefits over traditional manual labor. Automated facilities can work faster and more accurately than human workers, and they can operate around the clock without tiring and can collect data for monitoring the health status of the equipment and reduce waste. Automation can also help to improve safety in hazardous environments.

In recent years, industrial automation has been adopted by a number of industries, including automotive manufacturing, food and beverage processing, pharmaceuticals and electronics assembly. The trend is expected to continue as companies look for ways to improve efficiency and competitiveness.

Industrial automation can make production lines safe and uses logic-based programs to operate machinery and other industrial equipment technologies. The machine makes decisions without any human input based on its programming to unlock the efficiency of your work.

Though this may seem complicated at first glance, let us look at what Industrial Automation is through the lens of a small example.

What are Industrial Automation & Types of Industrial Automation solutions!

In modern factories and warehouses, the industry has always been automated. Industry automated systems employ controls such as computers, software, and robotic devices to perform traditionally manual work.

This advanced technology automatically manages industrial building equipment, significantly reducing operator participation. Automation systems generally comprise feedback loops and sensor software that can manually change operations to reach an optimal value if real-time data trigger them.

An industrial production process usually starts with raw materials from one machine, then gets processed by the next in a sequence of many.

Today, industrial automation is involved in the production line of many industries. Any given machine can be an electromechanical device such as motors or drills. Still, they can also be chemical machines like ovens and dryers - whatever it takes to produce the desired final product. However, thinking about an industry without a control system can be challenging.

Automation Project?

What is Industrial Automation, Their Types, and what Hierarchy of an Industrial Automation System?

The rapidly increasing competition in the industry requires quality products at a competitive price. Currently, the most influential way to solve this issue is industrial automation.

Industrial automation improves product quality and reduces production and design costs by integrating innovative technologies with services. Various sectors are considering different products to address their challenges with automated devices.

What is an example of industrial automation?

Advanced robotics can make crucial decisions in manufacturing operations. Robotic and CNC machines are excellent examples of today's modern automation equipment. Automated devices can control events in a variety of ways and increase efficiency by monitoring data which leads the production line to reduce waste.

Consider this example where a human hand would take control of what had to be done manually. Let us say we have an oven that needs a certain amount of heat but cannot go over it. Someone has been tasked with reaching the right temperature and then maintaining it for 30 minutes.

To ensure they do not miss anything, they check on the oven periodically while monitoring how much fuel is needed to go into the oven at any given time - all through trial and error. With industrial automation, though, everything takes care of itself.

Engines use valves to control systems for fuel supply to different engine parts. A computer also controls this valve so that it will open if a certain temperature threshold is met. As time passes and the optimum temperature has been reached, it closes again so that no excess gas is being fed into the engine, which would generate too much heat - this could damage other parts such as cylinders or pistons.

When 30 minutes have elapsed (indicated by an alarm from the computer), another set of commands takes over automatically until all tasks have been completed successfully; at this point, there is no need for human intervention whatsoever!

Increase Quality and Flexibility in Your Manufacturing Process

In the past, automated systems were intended to enhance productivity and save costs associated with manual operations. Nevertheless, automation is moving away from increasing quality and flexibility in manufacturing. The piston fittings for cars were manually installed in the engine with a rate of 1-1.5% in some cases. Automated machines carry out this task, averaging around 0.000-11% errors per hour.

Motivation for Industrial Automation!

The term 'Automation' was first coined by an engineer from Ford Motor Company, who pioneered industrial automation and manufacturing assembly lines. At the start of the Industrial Revolution, production was reliant on the human hand. Yet now, it relies solely on automated machines programmed to complete specific tasks without error when given instructions.

This type of automation is geared toward optimizing efficiency; for instance, if one device needs certain materials to finish its job and another machine requires a different material - instead of relying on what is being delivered at that moment which might cause setbacks due to miscommunications.

Each will send out requests for what they need through signals known as triggers so other sources can deliver them efficiently. With the start of the Industrial Revolution, industry and business strategy changes began to take effect.

The goals of Industrial Automation are:

Increase productivity

Reduce costs solutions (especially for human-based labor)

Improve quality

Use resources efficiently

Generate greater profit

What are the 4 types of automation?

Several automations has been identified in manufacturing, including (1) Fixed automation, (2) Programmed automation, (3) flexible automation, and (4) Integrated automation.

Fixed Automated System!

Now that we have seen a little about the basic layout of an industrial automation system let us continue exploring how Fixed Automation Systems work. Unlike Variable Automation Systems, which allow for manual modifications, Fixed Automations Systems operate at the same rate all day long with no change from one shift to another. These systems are typically found in manufacturing or food service industries, where high-volume production is key to success and productivity.

Programmable Automation System!

In a Programmable Automation System, the sequence of operations, as well as the configuration of the machinery, can be changed using electronic controls. This system typically takes significant time and effort to reprogram the machines and is most often used in batch process production to improve productivity.

Flexible Automation Solutions!

A Flexible Automation System is usually always controlled by computers and is often implemented where the product varies frequently. Based on the code given by an operator to a computer, it acquires the necessary tools or equipment needed to produce different effects- just like how there could be countless versions of one car model depending on its year or trim level. CNC machines are one of the best examples of this system.

Integrated Automation System!

An Integrated Automation System is a set of independent equipment, processes, and data, all working synchronously under the command of control systems to implement an automation system for production. In other words, it is when you use CAD software or computer-controlled equipment such as robots or computers to do your work instead of relying on people.

Industrial Automation Process!

There are many different ways to depict what an Industrial Automation Process entails. Still, this simple hierarchy of three-stage representation of a typical Industrial Automation Application is the easiest way.

Supervisor Level

At the pinnacle of all hierarchies, supervisors are responsible for overseeing processes until they run smoothly. This position typically entails having multiple Industrial PCs, often available as Desktop Panel or Rack-mounted Computers.

These computers run on standard Operating Systems with a particular software package from the supplier that provides them with industrial process control capabilities. The primary purpose is process visualization and parameterization. A unique industrial Ethernet is used for communication, which can be gigabit LAN or any wieless topology (WLAN).

Control Level!

A Programmable Logic Controller is a device that executes automation-related processes. PLCs are usually microprocessor-based and often use 16-bit or 32-bit microprocessors; they manage these processes because they provide real-time computing capability. A PLC can interface with multiple input/output equipment - such as sensors, lights, and motors - and communicates with other systems through different types of wireless communications protocols - like CAN.

Field Level!

Various devices in the field (such as sensors and actuators) are field-level equipment in the manufacturing process. Sensors like temperature, optical, pressure, etc., and actuators like motors, valves, switches, etc., are interfaced to a PLC through a field bus. Point-to-point connections allow for communication between these devices and their corresponding PLCs. Wired or wireless networks may be used here depending on factors such as cost and mobility, enabling diagnostics of the various components connected throughout the installation of machines.

More About Industrial Automation Solutions!

In addition, an industrial automation solutions system also requires two significant systems. These are

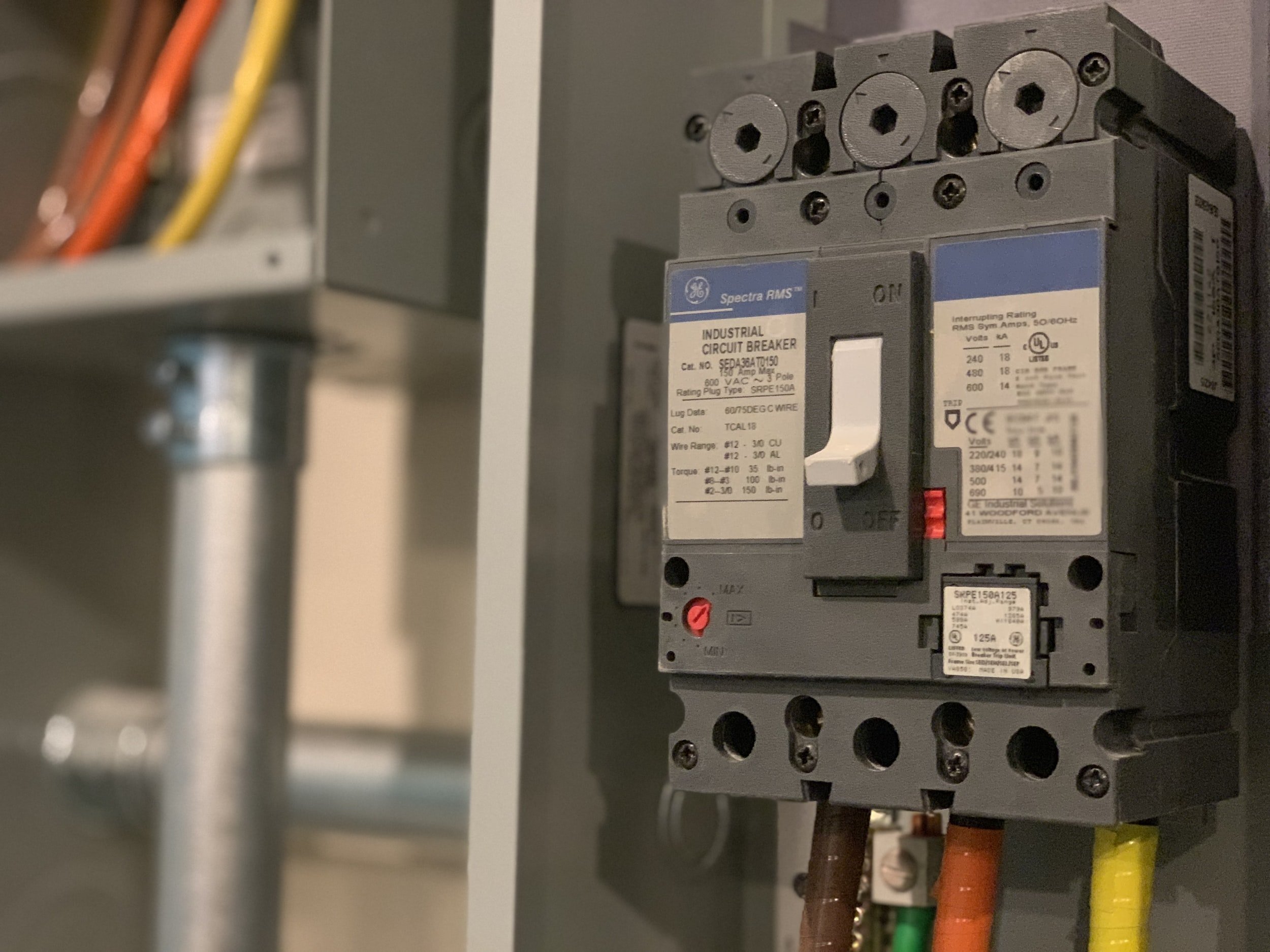

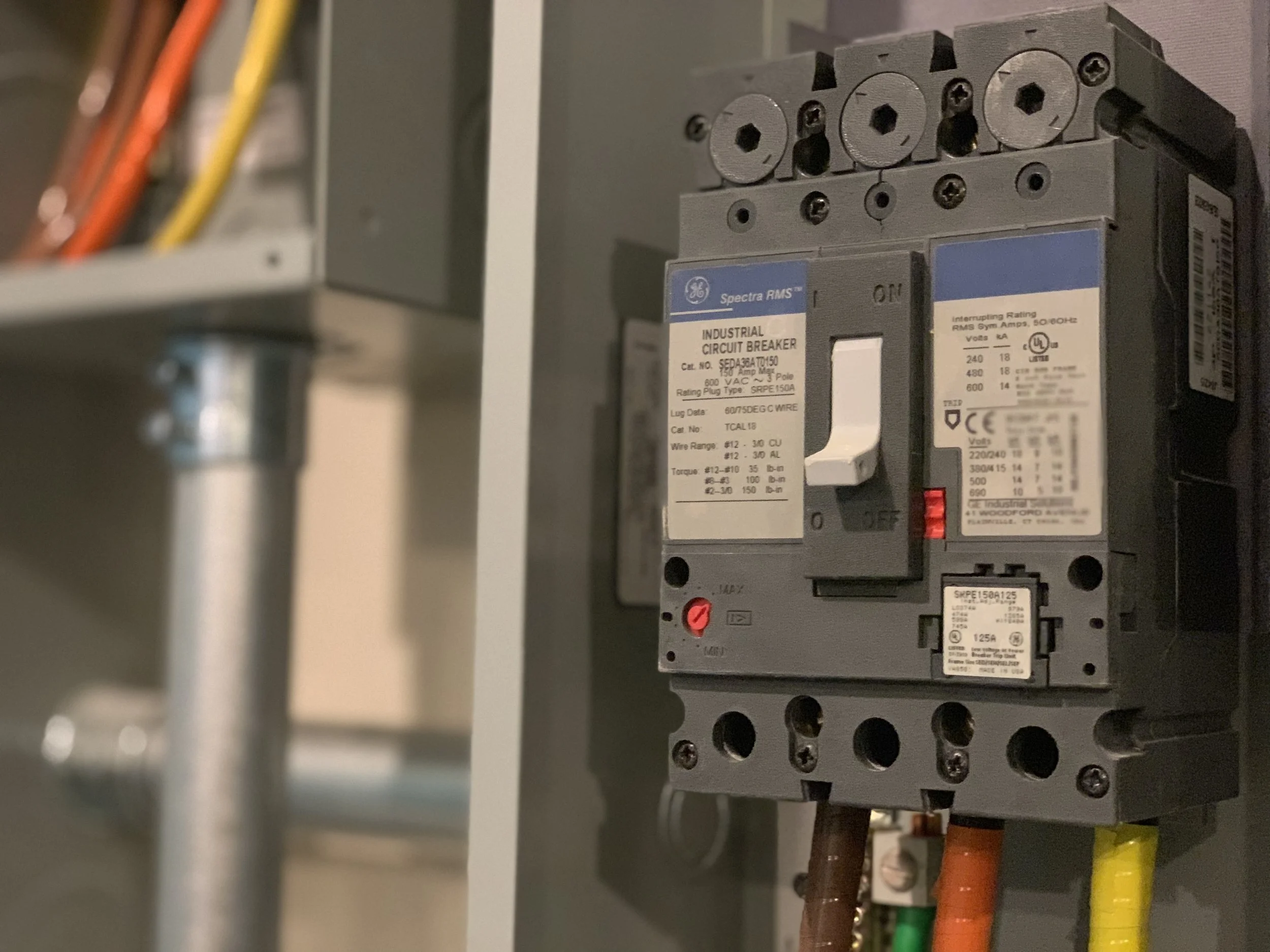

Industrial Power Supply

Security and Protection

Power requirements of different systems at different levels of the hierarchy can be significantly different - for example, PLCs usually run on 24V DC. In contrast, heavy motors are either powered by one of three phases of AC. Therefore, various proper input power supplies are needed to function without any trouble.

Advantages of Industrial Automation

Let's have a look at the advantages of industrial automation:

Reduced operating costs: Industrial automation reduces healthcare and employee pay time. Industrial automation is also not dependent upon other workers' benefits like pension protections, bonus programs, etc.

Even if this initial expense is highly significant, it saves wages and thus leads to substantial savings for the company.

Maintenance costs associated with machines for industrial automation are lower because they rarely fail.

When this fails, only technicians and computer technicians must do it.

Human operators doing tedious jobs can be replaced with automated equipment.

This eliminates the need for human operators to do tasks in hazardous environments involving extreme temperatures, pollution, intoxicating elements, or radioactive substances.

Tasks typically challenging for a person may seem easy to control system.

These include lifting heavy and large loads, working with highly tiny objects, etc.

Production goes much faster and less costly when the operator is automated.

Automation also provides quality control checks for consistency and uniformity.

The economy will improve significantly, positively impacting the standard of living across society.

Now, let's have a look at the disadvantages:

Jobs are being lost due to the increasing popularity of machines and automation.

With most tasks involving manual labor, it is not easy to automate everything with today's technology.

Some things cannot be automated—for example, goods with irregular shapes or varying dimensions.

Machines may only work well for large-scale production runs, repetitive processes, or items where consistency is key.

Automation systems require lots of time and money up front; they also need people skilled in service and maintenance.

What is the use of industrial automation?

Industrial Automation Technology provides companies with enhanced security and a reduced cost while increasing product development quality. Having these advantages helps companies increase profits and productivity.

What is the use of industrial automation?

Industrial Automation Technology provides companies with enhanced security and a reduced cost while increasing product development quality. Having these advantages helps companies increase profits and productivity in the production line.

What Can We Build For You?

Regardless of your industry or industrial automation needs, IndustLabs has the experience and manufacturing facilities to design and build your automation equipment. We have an experienced engineering and quality control team dedicated to providing the best solution to your automation needs..

Our manufacturing facility in Dallas, TX is staffed with experienced engineer technicians, ensuring your automation equipment meets safety and performance criteria. At IndustLabs, we feature a variety of automation solutions. If you have questions regarding any of our products, their function or applicability to your project, give us a call, +1(877)945-2272 or contact us for information without obligation.

Automation Project?