Motor Control Centers Design, Installation, and Manufacturing

Powering Efficiency and Reliability in Industrial Applications

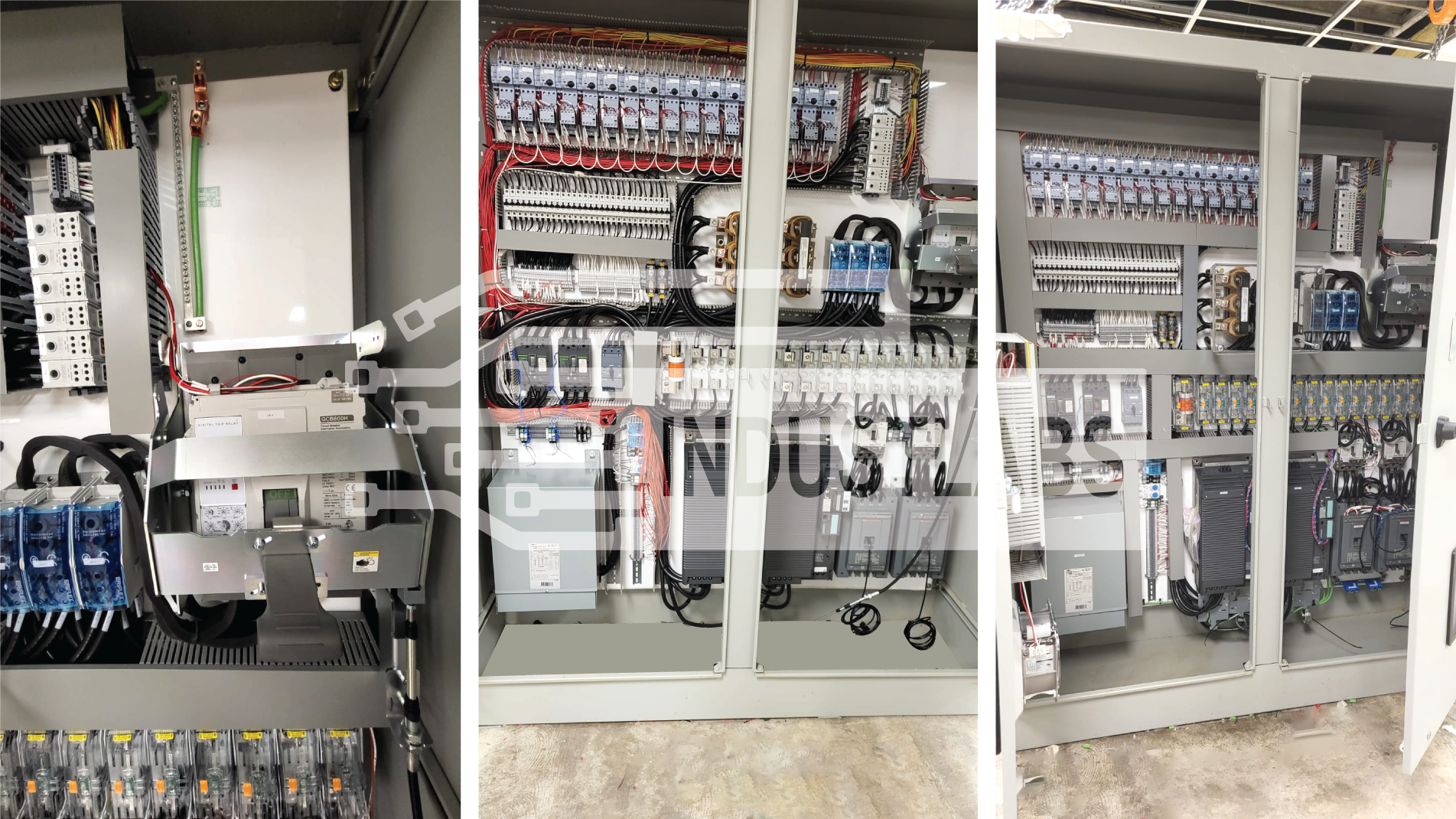

IndustLabs offers Complete Motor Control Center Solutions from Design to installations and Manufacturing, Motor Control Centers are centralized compartments comprising various feeder circuits for motor control. Whether you are aiming for efficient energy management or looking to optimize your industrial processes, MCCs play a pivotal role in streamlining operations and ensuring safety. Contact Us for your free no obligation quote

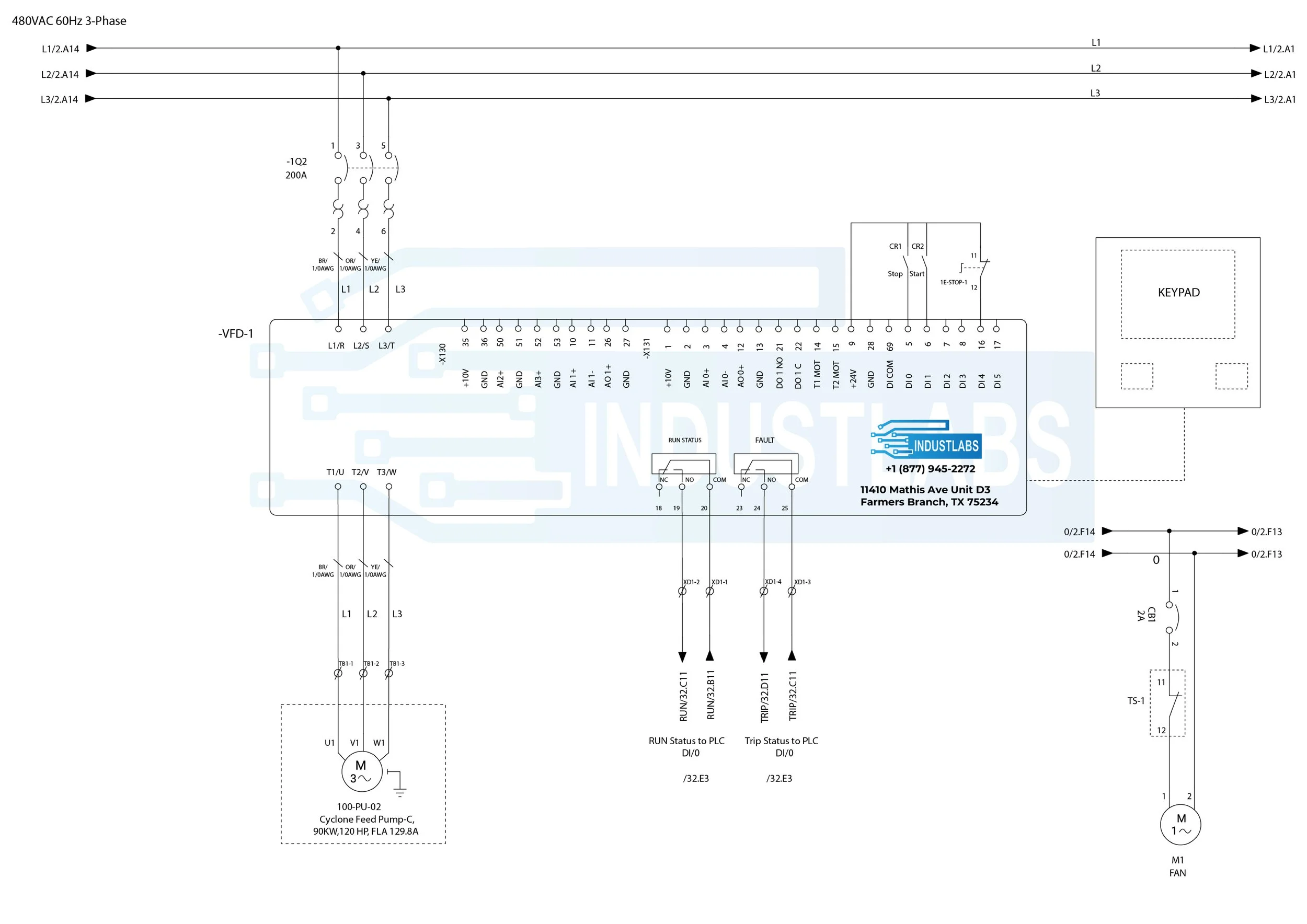

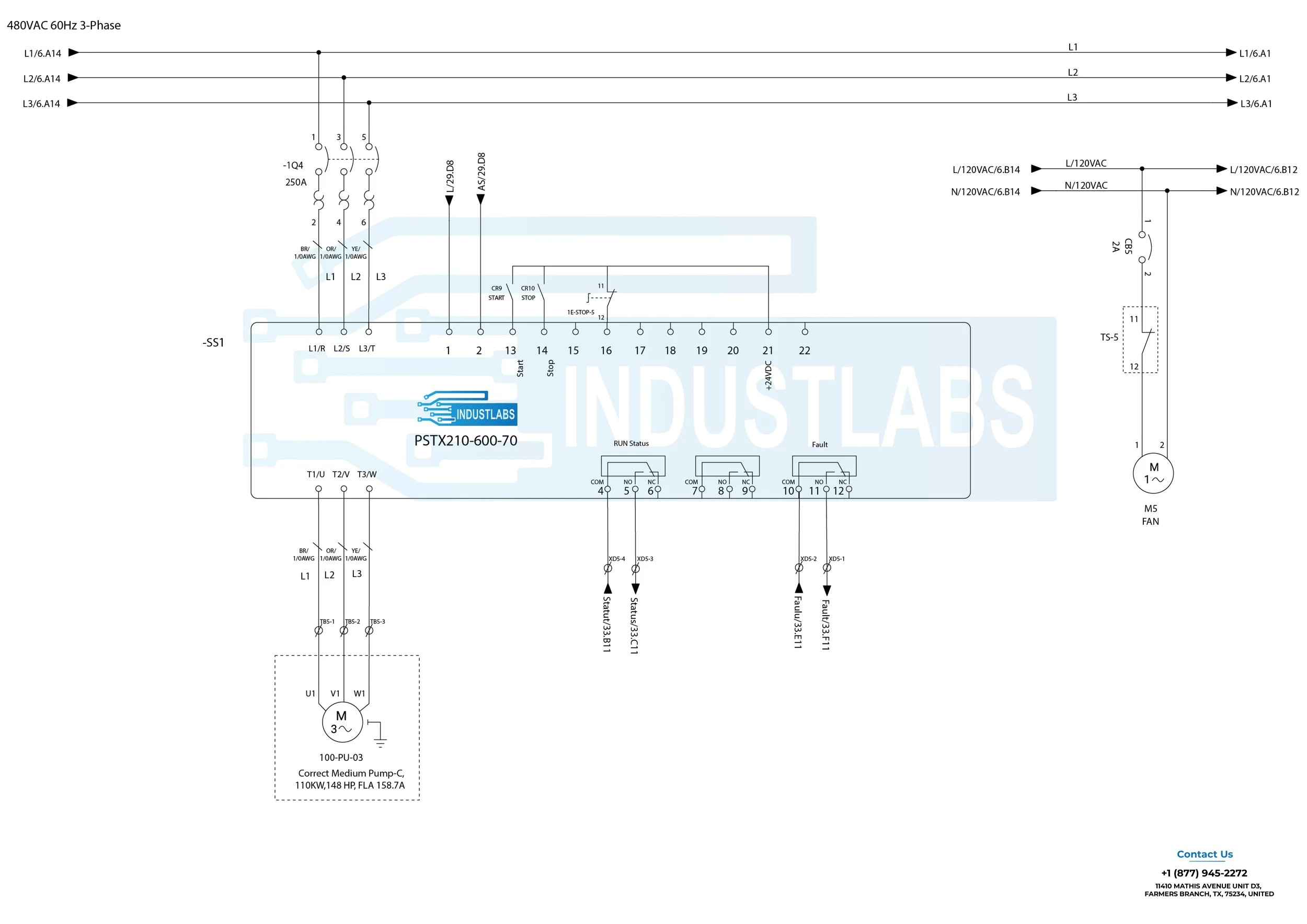

These systems integrate programmable controllers, variable frequency drives, circuit breakers, and other essential components to provide a cohesive solution for motor management like Buckets and compartments. They act as the nerve center for controlling, monitoring, and protecting the complex machinery that drives modern industry.

We especially focus on low-voltage and medium-voltage MCCs, as these are the most commonly utilized in the United States and many other parts of the world. We will dive into the technical specifications, industry applications, safety protocols, and advancements in MCC technologies, keeping a keen focus on real-world applications and standards.

Why Choose Motor Control Center and What it is?

A Motor Control Center (MCC) is a centralized assembly that comprises multiple motor starter sections, or “buckets,” each designed to control a single motor or a group of motors. It serves as the central point for the management of electrical motors, integrating key functionalities such as starting, stopping, monitoring, and protecting these vital components in industrial settings. here are some key factors of MCCs.

Starting Motors: MCCs house devices like contactors and soft starters that energize motors for operation.

Stopping Motors: Integrated circuit breakers and disconnect switches can swiftly disconnect power supply, facilitating rapid motor shutdown.

Monitoring: Components like PLCs (Programmable Logic Controllers) and HMI (Human-Machine Interface) are often incorporated for real-time monitoring of motor conditions.

Protection: Overload relays and circuit breakers within the MCC safeguard the motors against overcurrent, overheating, and other electrical anomalies.

Voltage-Based Classifications of MCC:

Low Voltage MCCs: Our Low Voltage MCC solutions are intricately engineered to power motors operating on voltages below 1000 volts, fully complying with regional and global standards. Specifically in the United States, our MCCs are designed for seamless integration with common industrial voltages of 480V, 240V, and 120V.

Low Voltage MCCs offers high-performance packaging that accommodates a broad spectrum of motor control needs. Utilizing state-of-the-art components like advanced contactors, circuit breakers, and overload relays, our MCCs ensure peak operational efficiency.

Medium Voltage MCCs: Medium Voltage MCCs are engineered to manage electrical applications that operate at voltages exceeding 1000V. These systems are integral components in large-scale, sophisticated industrial settings where higher voltage levels are required for operational efficiency.

these MCCs are equipped to handle the intense power requirements of heavy machinery, large motors, and other high-demand electrical equipment. They comply with IEEE, ANSI, and IEC standards for medium-voltage systems, thereby ensuring safety, reliability, and efficiency.

The United States primarily uses a standard rating of 65000 volts for its MCCs. This metric should be closely matched to your application's requirements to prevent system failures and ensure safety.

Let industlabs help you in Next big idea! Call Now

Roles and functions of MCC:

-Distribution of Power: The primary objective of bus bars in a Motor Control Center (MCC) is to ensure efficient, reliable, and uniform distribution of electrical power across multiple circuits, enhancing the operational integrity of industrial machinery.

The bus bars typically operate as a four-conductor system, including three-phase conductors L1, L2, L3, and a ground conductor, compliant with industrial voltage norms like 480V, 240V, and 120V in the United States. These bus bars are designed to handle large current flows. Amperage capacities can range from 600 amps to as high as 3000 amps, contingent on the specific industrial application and load requirements.

Our bus bars are rated to handle short-circuits up to 65KVA, adhering to USA standards, thus offering an additional layer of protection against electrical anomalies.

Material Selection: It is the most critical factor influencing the efficiency, reliability, and safety of the entire MCC system. Material selection impacts electrical conductivity, heat dissipation, and corrosion resistance, among other variables. IndustLabs Recommends Copper as it is often the material of choice when it comes to constructing bus bars in MCCs for a variety of compelling reasons

Superior Heat Dissipation

High Electrical Conductivity

Corrosion Resistance

Cost-Effectiveness

Copper bus bars in MCCs typically adhere to rigorous industry standards, ensuring they meet the requisite electrical and mechanical performance criteria.

Buckets in Motor control centers:

The primary role of buckets in an MCC is to serve as segregated, modular units that accommodate individual motor control elements like starters, contactors, and circuit breakers. These buckets play a pivotal role in streamlining management and enhancing the safety of complex electrical systems. its key feature includes:

Isolation for Safety and Manageability

Electrical Independence

Wiring Infrastructure

Design Flexibility

MCC Containers:

MCC Containers offer an innovative and flexible solution to motor control, especially suitable for dynamic operations that require portability and quick setup. These modified shipping containers are outfitted with MCC buckets and are designed to be plug-and-play systems. The floor layout is adapted to accommodate the wiring and plugs that go through the bottom of the MCC buckets. In addition, the container includes climate control features such as insulation and air conditioning to ensure a stable operating environment. Safety measures like depressurizing, container doors, emergency exit doors, and access control doors are all incorporated. Once delivered, clients can simply connect their systems and begin operations. If the situation calls for it, the entire container can be moved to a new location, offering an unparalleled level of modularity and flexibility.

Industries we Serve

-

We offer energy-efficient MCC designs with integrated VFD (Variable Frequency Drives) for precise climate control, reducing operational costs.

-

IndustLabs is very popular in planning, design, and construction of MCC buildings. Our solutions encompass not just the MCC panels but also the civil, electrical, and environmental engineering aspects to create a purpose-built facility. We incorporate fail-safes, cooling systems, and advanced fire suppression technologies to ensure the uninterrupted operation of your critical motor control systems.

-

Our robust MCC configurations meet high-reliability criteria essential for power distribution, including customized busbar systems for high current capacities.

-

Specialized MCCs with high short-circuit ratings and resistance to environmental factors like corrosion and UV radiation.

-

We provide intelligent MCC solutions that integrate PLCs (Programmable Logic Controllers) for enhanced automation and operational efficiency.

-

We are at the forefront of innovative MCC designs tailored for next-generation industrial applications.

-

We offer MCCs with advanced monitoring capabilities and custom-designed starters to meet the exacting standards of semiconductor fabrication.

-

We offer Modular MCCs designed for scalability, easily adapted to a wide range of construction machinery and material handling equipment.

-

We offer MCC designs with enhanced safety features including circuit breakers and overcurrent protections specifically engineered for the demanding conditions of mining operations.

Why Choose Us?

As a leading provider of industrial automation and control systems, we have years of experience in delivering high-quality solutions tailored to our clients' needs. Our team of experts will work closely with you to understand your requirements and design an MCC solution that meets your unique specifications. We ensure superior product quality, seamless integration, and exceptional after-sales support, making us your trusted partner in enhancing your industrial processes.

Take the Next Step Towards Streamlined Motor Control!

Investing in our Motor Control Center will revolutionize your motor control operations, enhancing efficiency, reliability, and safety in your facility. Don't miss out on the opportunity to optimize your industrial processes and achieve significant cost savings. Contact us today to learn more about how our MCC can transform your motor control system.

“We were unable to locate a stock enclosure that would fulfill the specifications of a job. Industlabs was able to design a custom enclosure to fit the application. ”