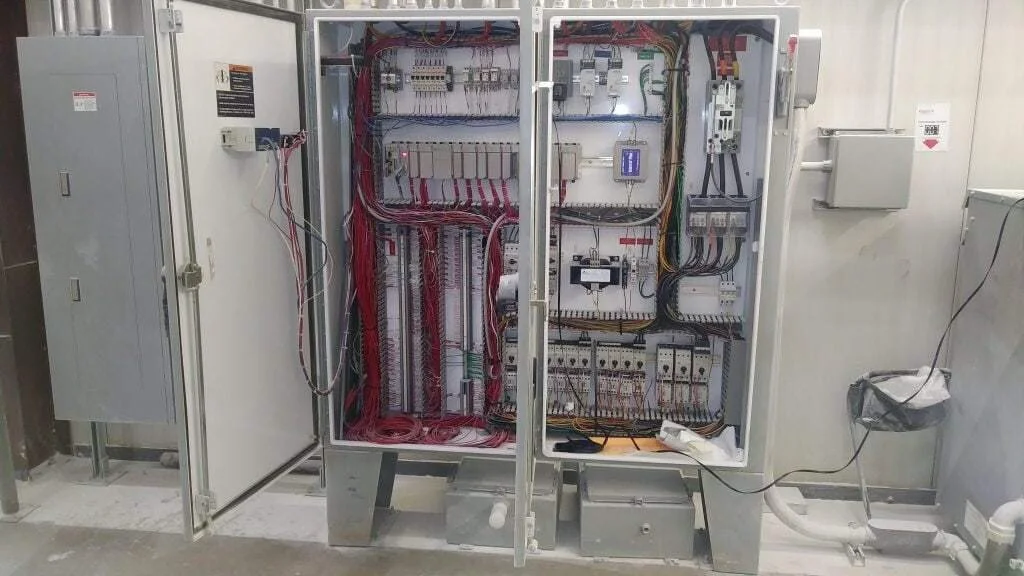

Case Study: IndustLabs developed and installed a thermal system for the production of the thermoelectric module semiconductor material to control temperature and the motion via a Programmable Logic Controller (PLC), Servo Motion System, a process controller for precise temperature control, a Human-Machine Interface (HMI), and a Battery BackUp System (BBS).

Double Digit Production with Allen Bradley PLC & RX Logic 5000

Case Study: IndustLabs developed and installed a thermal system for the production of the thermoelectric module semiconductor material to control temperature and the motion via a Programmable Logic Controller (PLC), Servo Motion System, a process controller for precise temperature control, a Human-Machine Interface (HMI), and a Battery BackUp System (BBS).

Reduces Product Waste with Precise PID Temperature Control

IndustLabs was able to eliminate 90% of the waste of the Single Cup Coffee Filled Operation by implementing a precise temperature control system. The temperature control system involved 32 Proportional-Integral-Derivative (PID) feedback loops for temperature control, a Human-to-Machine interface, and all custom software to operate and run equipment.